In today’s diversified market environment, material and product requirements across industries are increasingly specialized and individualized. Simker keenly recognizes this trend and, with technical expertise and extensive experience, provides customers with customized solutions to meet their unique performance and dimensional requirements for diaphragms, rubber bladders, accumulators, and anti-vibration mounts.

Since establishing the R&D team in 2003, Simker has successfully developed tailor-made core components and technical support for well-known enterprises in various industries, including mining machinery, port equipment, automotive manufacturing, medical equipment, wind power generation, aerospace, and other industries. These successful cases demonstrate the feasibility and reliability of Simker’s customized solutions, offering valuable references for new clients. Simker’s team is capable of quickly identifying specific challenges across different industries and delivering effective solutions.

Led by company founder Mr. Zhao Huijiang, a UK Chartered Engineer and IET member, the R&D team has over two decades of deep industry experience. Mr. Zhao is a specialist in material formulations, rubber diaphragm design, and accumulator engineering.

The team consists of experts and senior technical professionals who select suitable materials from Simker’s extensive material library based on client drawings, technical specifications, and operating environments. They then optimize these materials using proprietary modification and alloying technologies. For high-pressure applications, rubber is optimized to withstand extreme loads without deformation.

For corrosion resistance, inhibitors are added and molecular structures are adjusted to enhance chemical stability and durability.

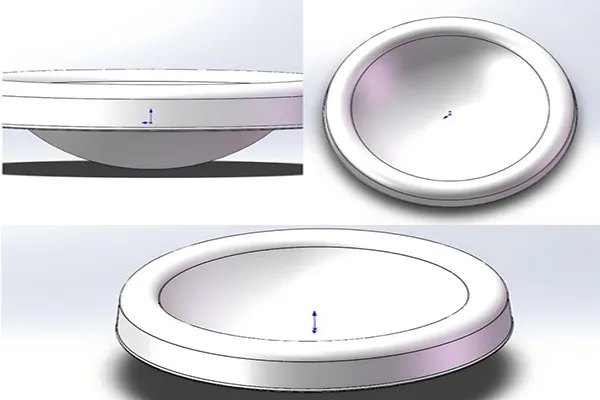

During the product design phase, Simker employs advanced Computer-Aided Design (CAD) and Computer-Aided Engineering (SOLIDWORKS) tools to perform structural simulation and analysis, ensuring optimal dimensions and geometry while maintaining required performance standards. This approach not only improves product functionality but also effectively reduces manufacturing costs.

Simker currently holds 2 international invention patents and nearly 30 national invention patents, providing strong technological support for customized product development.

Simker maintains strict quality control throughout the entire process from raw materials to finished products. Key production stages are continuously monitored, with in-process inspections ensuring process stability and product consistency.

All product performance testing complies with international standards (e.g., ISO 48) and covers hardness, tensile strength, elongation at break, and compression set.

The laboratory is equipped with rheometers, 3D projectors, tensile testers, and aging chambers, enabling comprehensive performance evaluation. All test data are managed through the LIMS system, ensuring full traceability.

With a certified ISO 9001 quality management system and rigorous internal corporate standards, Simker delivers rubber diaphragms, rubber bladders, and anti-vibration mounts of consistent quality.