Simker adheres to a management philosophy of continuous innovation and process optimization. Quality assurance begins at the source, where all raw materials undergo strict inspection to ensure they meet production standards. During manufacturing, refined process workflows and rigorous inspection mechanisms are established to maintain consistency and reliability. The company has obtained ISO 9001 quality management system certification and established enterprise standards filed with the Bureau of Quality and Technical Supervision. Standardized management ensures that Simker’s rubber diaphragms, rubber bladders, anti-vibration mounts deliver stable and dependable performance that clents can trust.

All incoming raw materials are subjected to detailed testing to verify purity and formulation accuracy. The purity of natural rubber and the composition of additives are carefully checked to confirm compliance with production requirements. Each batch is tested using precision instruments such as density testers to evaluate material uniformity and consistency.

Throughout key manufacturing stages, including mixing, calendering, and extrusion, equipment operating parameters are continuously monitored to ensure process stability. Semi-finished products are tested at each stage. Plasticized rubber is inspected for plasticity, mixed rubber is tested for density, hardness, and compound viscosity while calendered and extruded sheets are monitored for thickness and surface quality in real time.

Product properties are tested in accordance with ISO 48 and other international standards. Tests include hardness, tensile strength, elongation at break, and compression set to ensure that each product meets the required specifications.

Moving die rheometer

Moving die rheometer Two-stage vulcanization chamber

Two-stage vulcanization chamber Aging oven

Aging oven Thickness gauge

Thickness gauge Optical projector

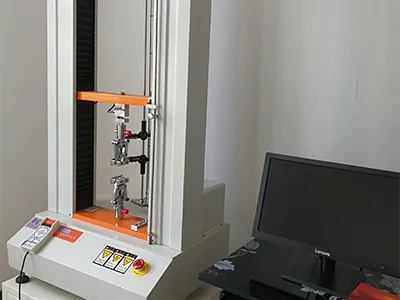

Optical projector Tensile testing machine

Tensile testing machine Hardness tester

Hardness tester

Simker is an integrated enterprise specializing in the R&D, production, and sales of advanced rubber diaphragms and bladders. With over 20 years of experience, the company focuses on specialized rubber diaphragms, accumulator bladders, and shock absorbers, accumulating extensive technical expertise and application experience.